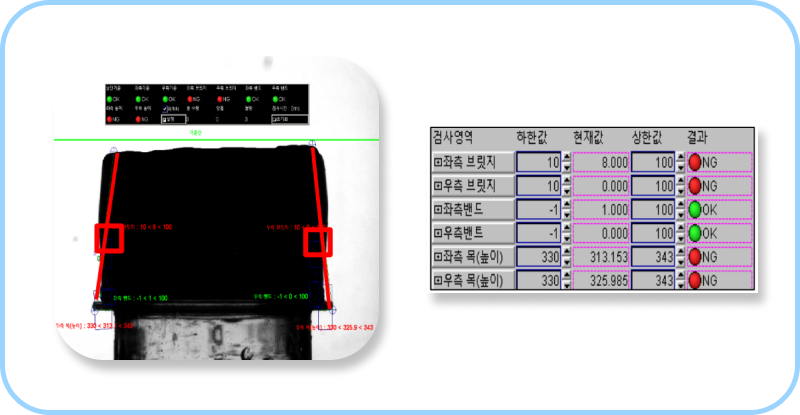

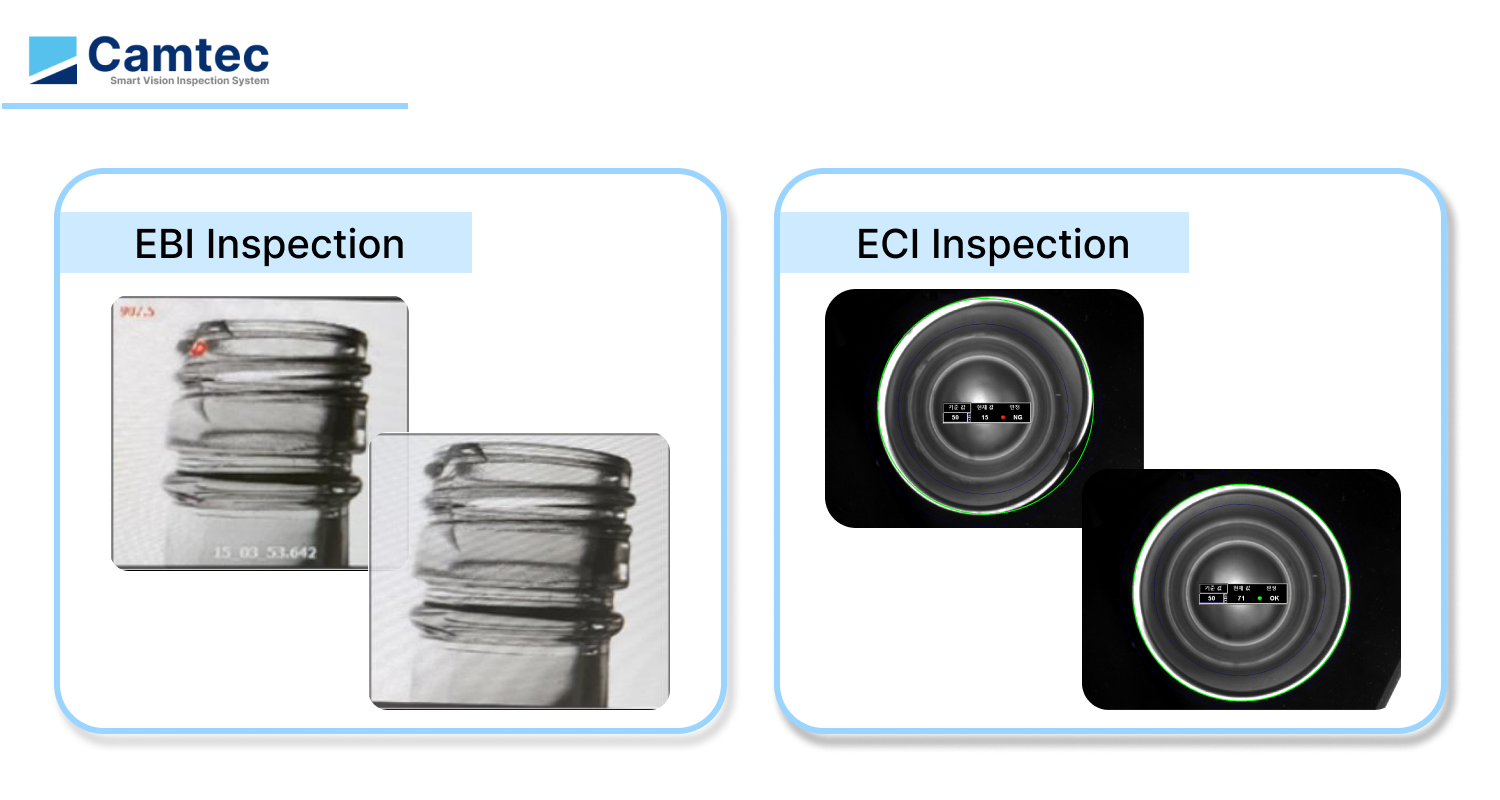

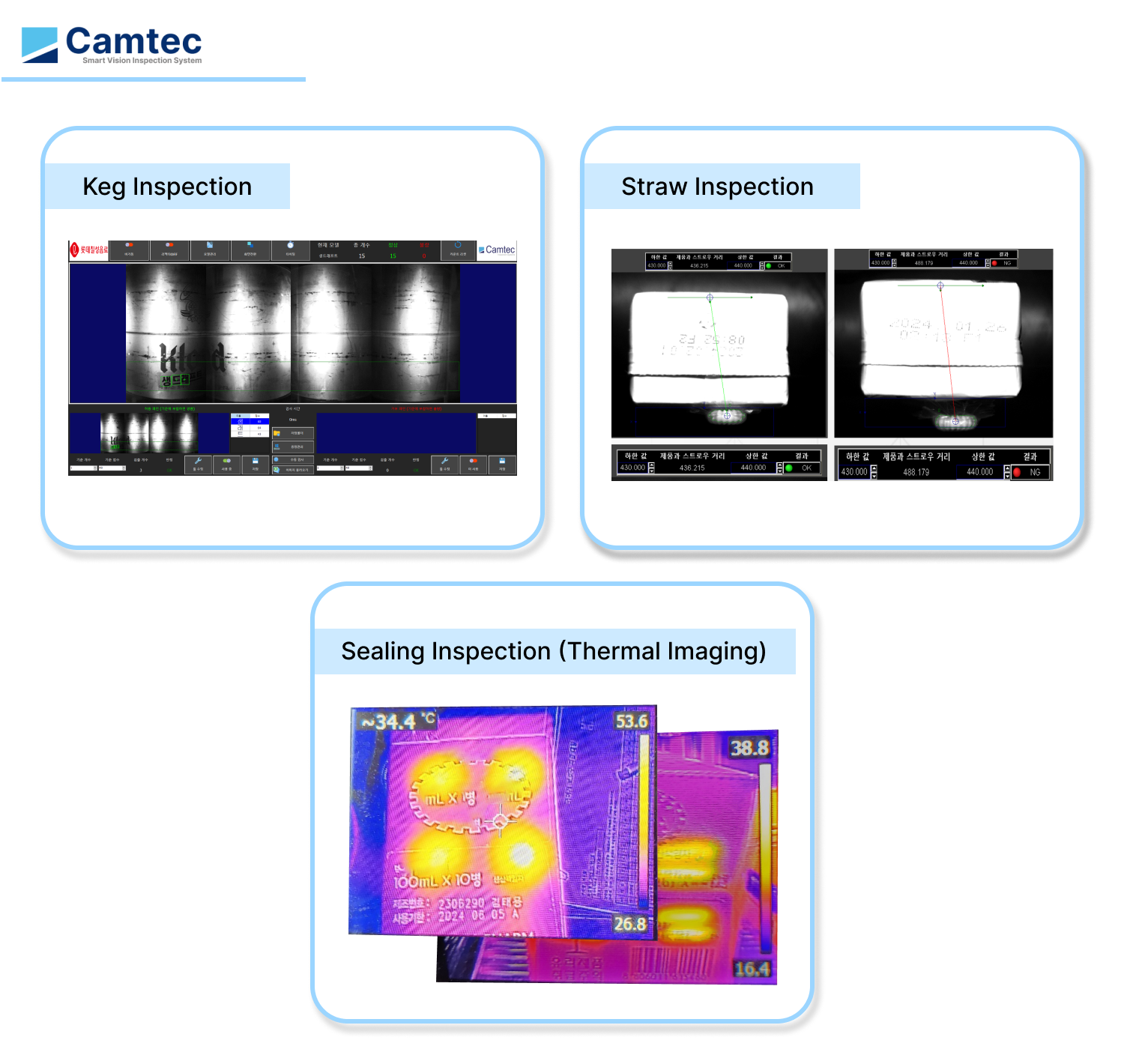

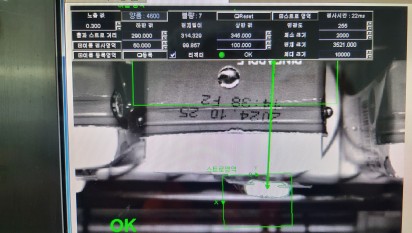

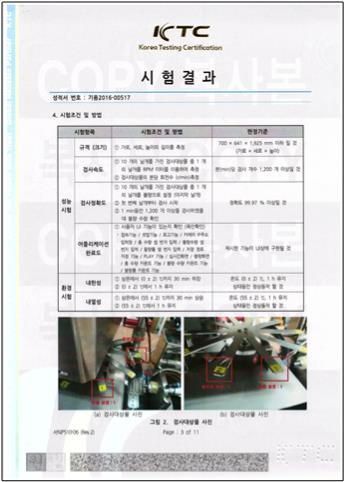

Keg inspection

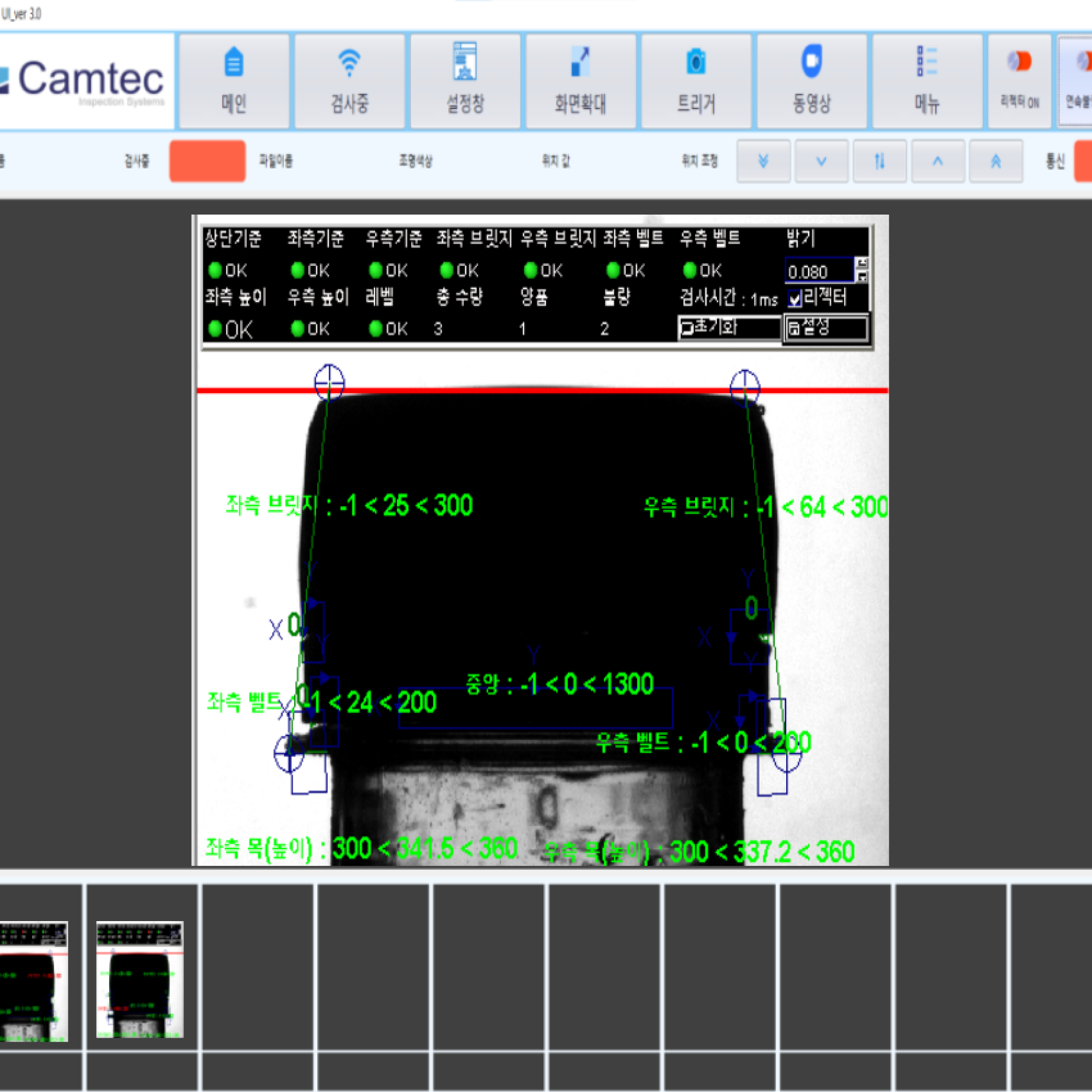

Keg inspection is an examination conducted to verify the quality of kegs used for transporting beverages. The inspection precisely detects external defects, leakage, capacity, valve alignment, and the presence of closures, highlighting the location and inspection items in red and saving the image when defects are detected.

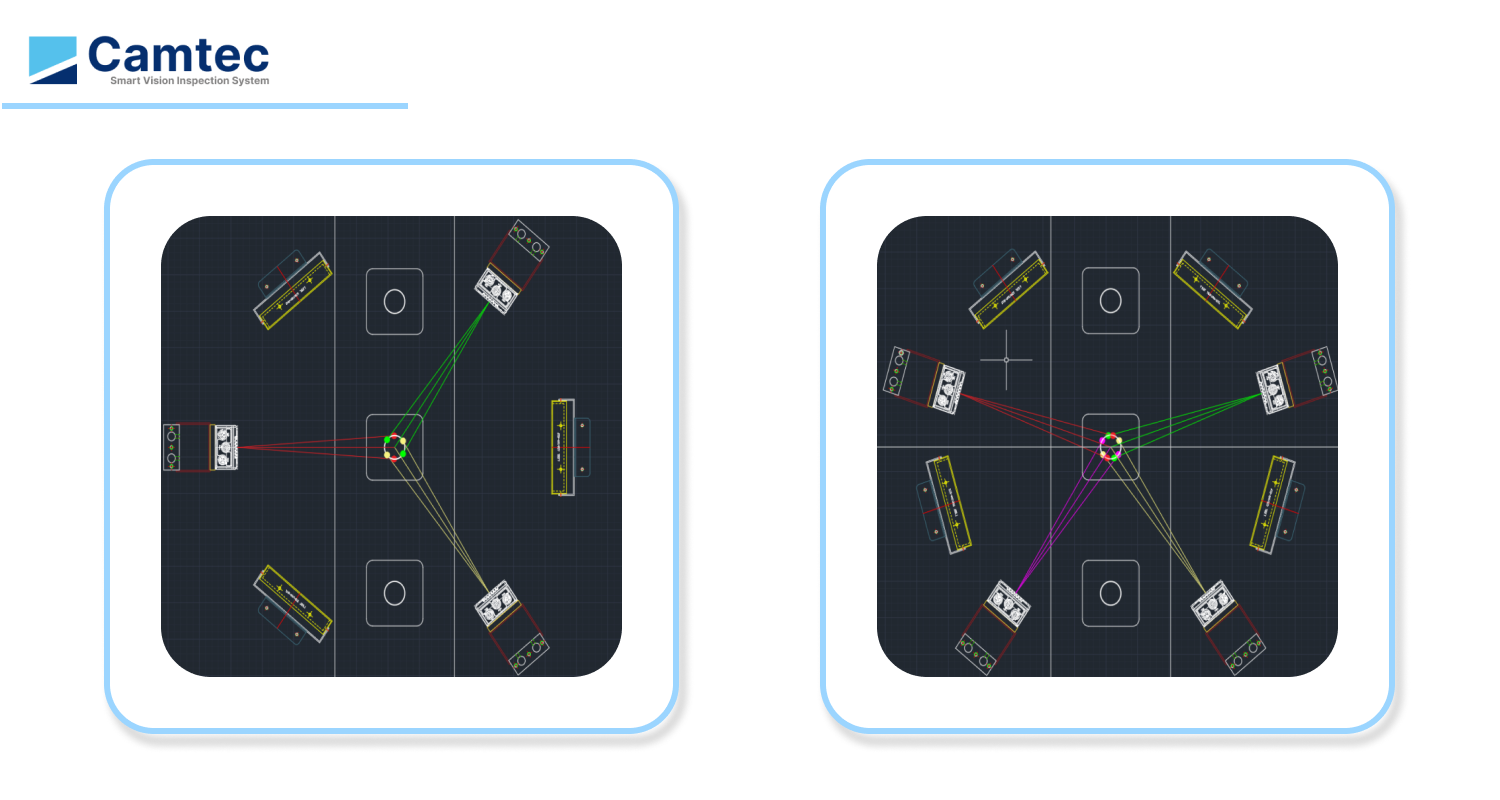

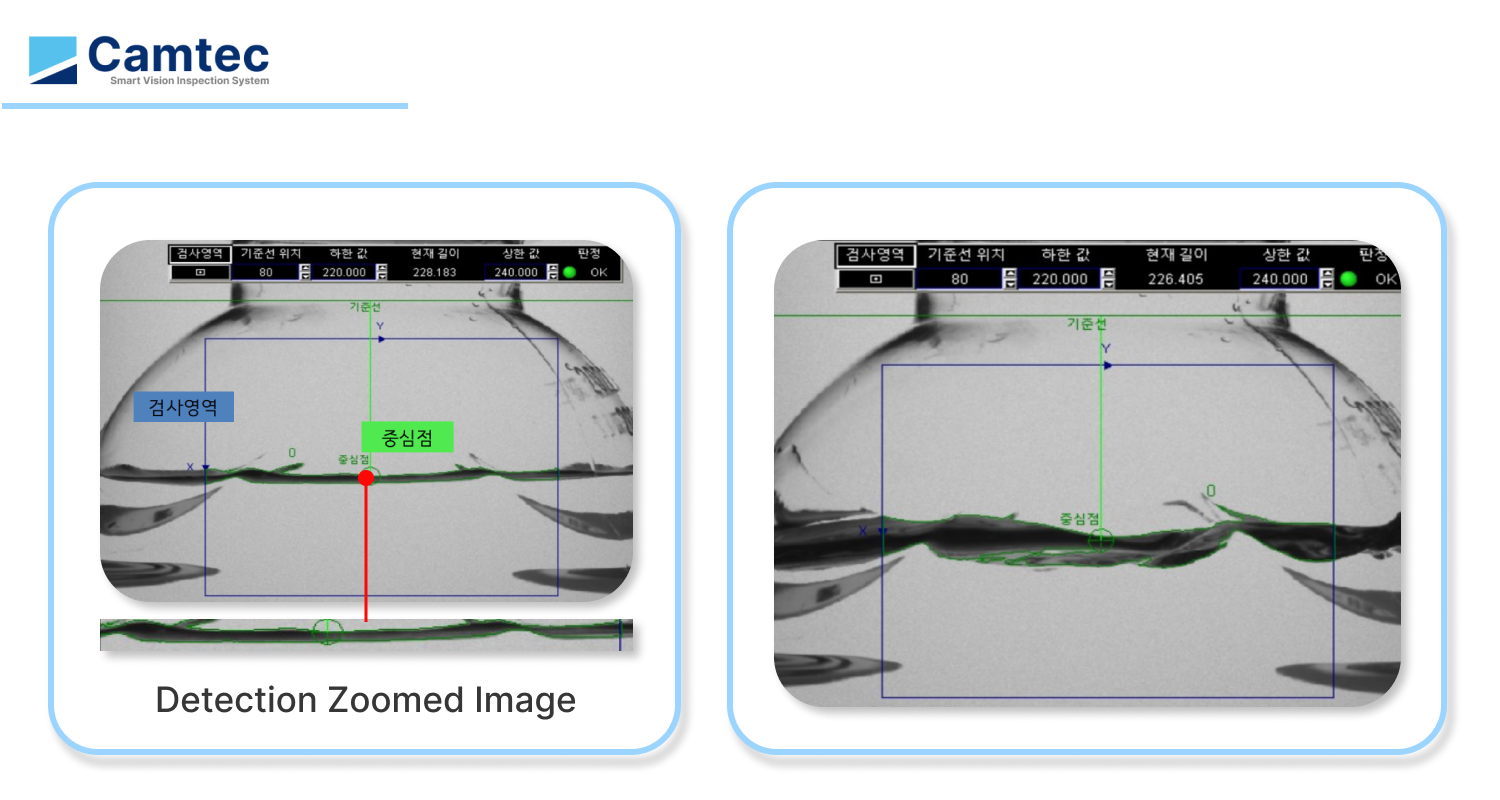

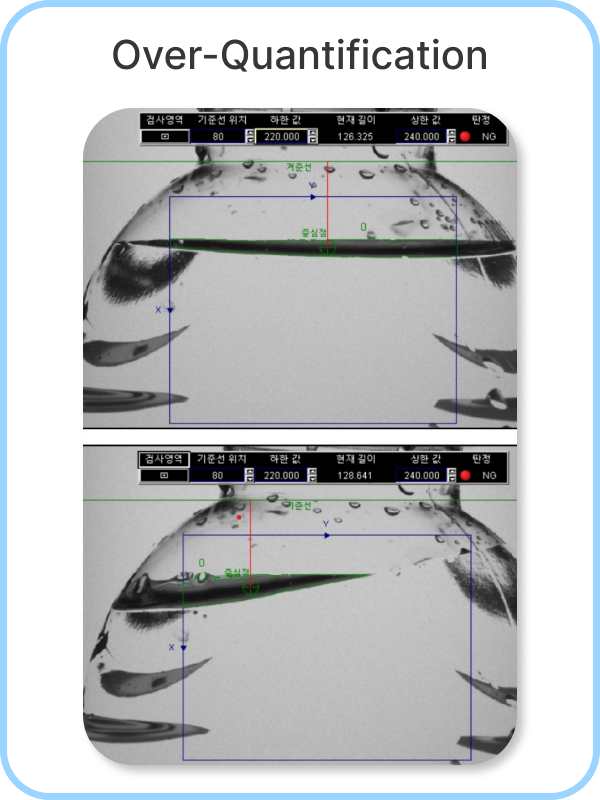

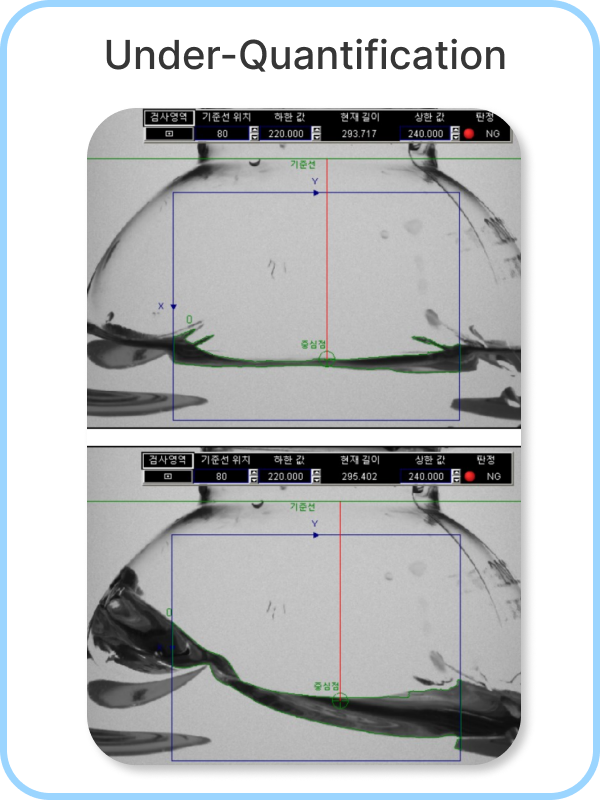

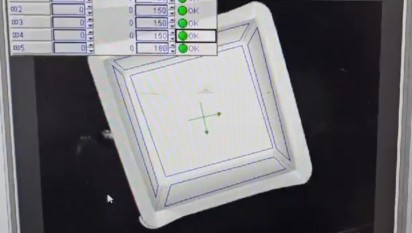

Straw inspection

Straw inspection is an examination conducted to verify the quality of straws. The inspection precisely detects the length, thickness, twisting, contamination, and more of the straw, highlighting the location and inspection items in red and saving the image when defects are detected.

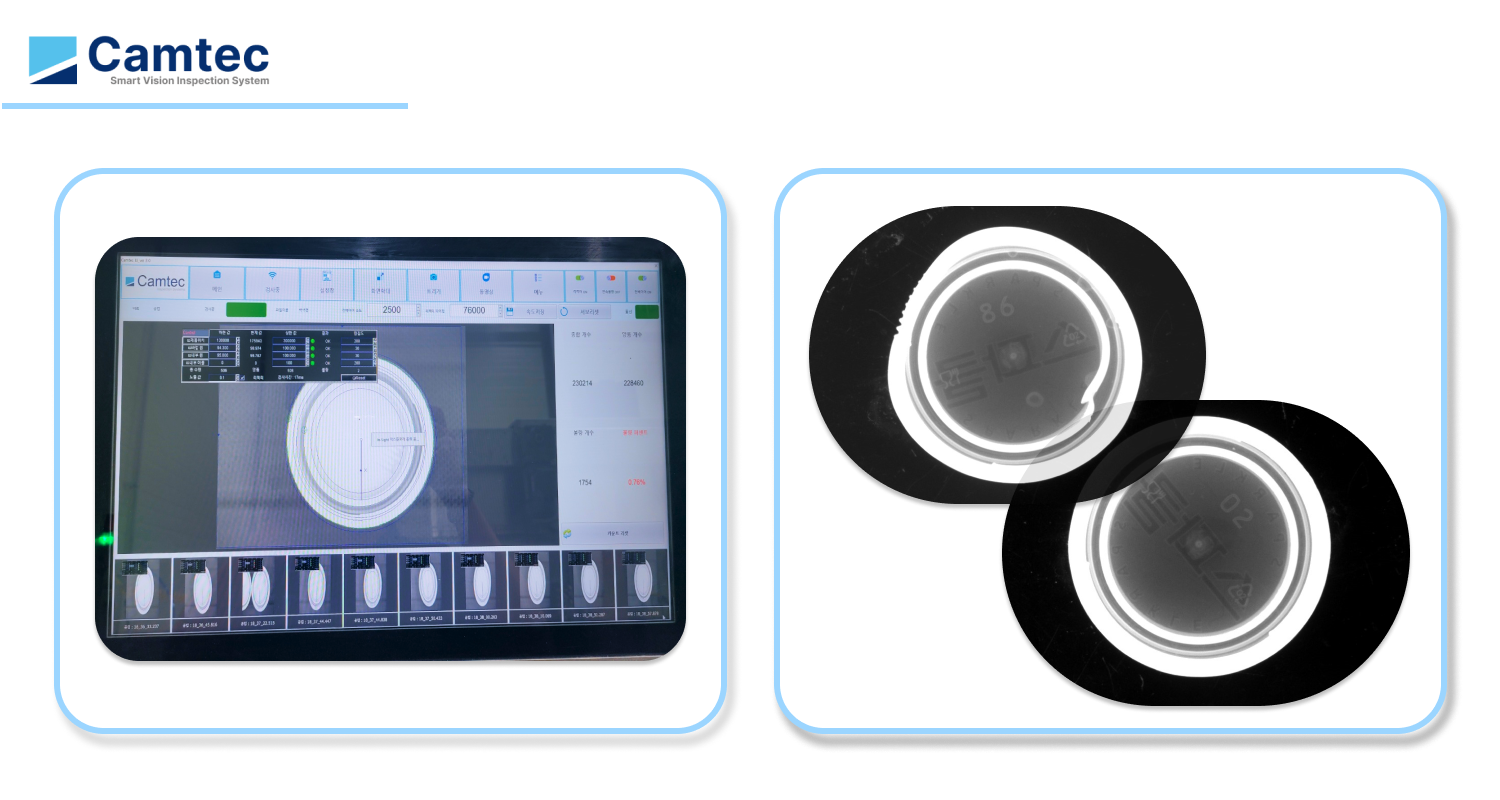

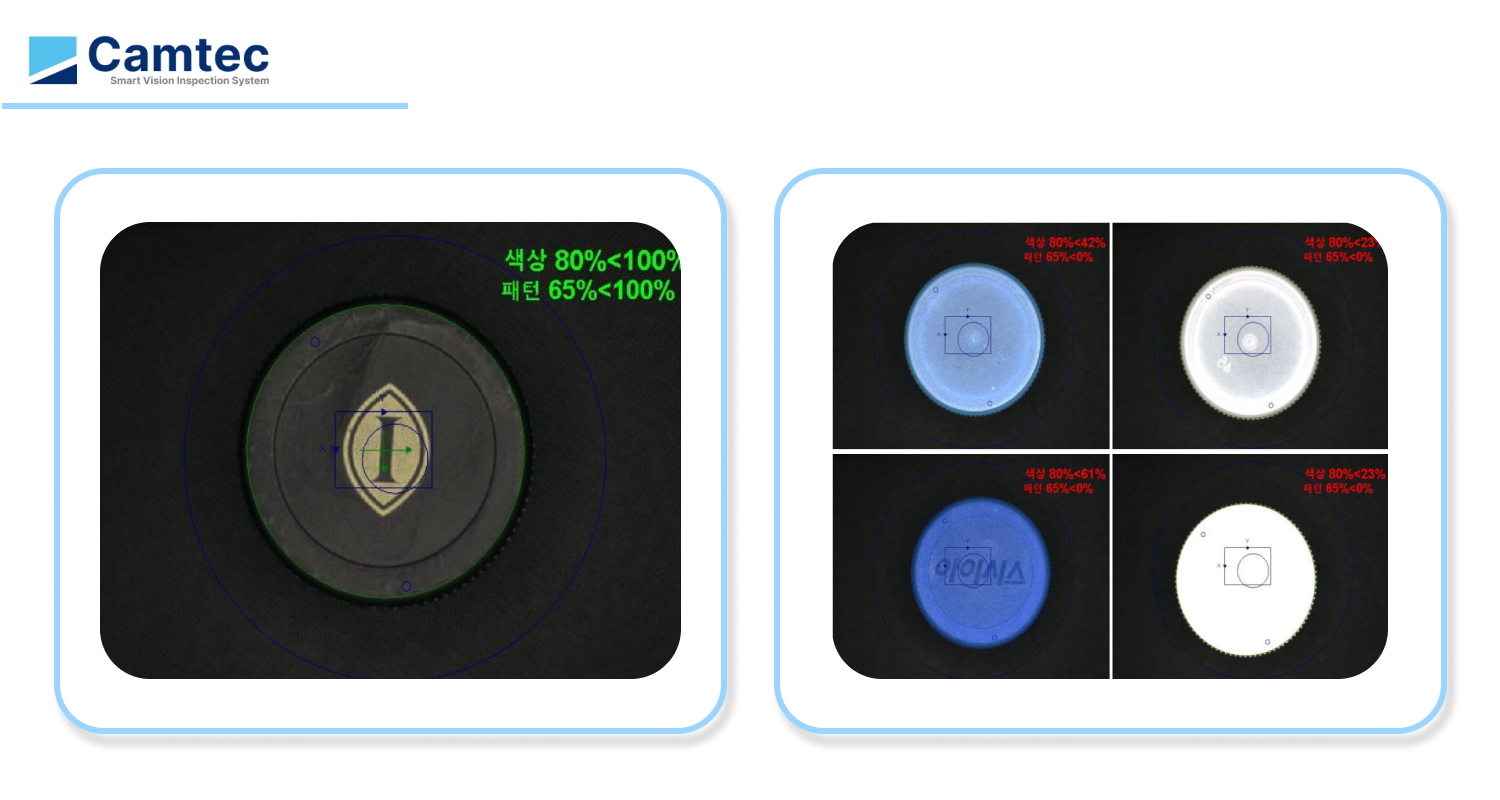

Sealing Inspection (Thermographic)

Sealing inspection is an examination conducted using thermographic technology to confirm the presence of sealing responsible for product containment. The inspection analyzes the heat patterns of the sealing area using a thermographic camera, precisely detecting the sealing status, and highlighting the location and inspection items in red and saving the image when defects are detected.

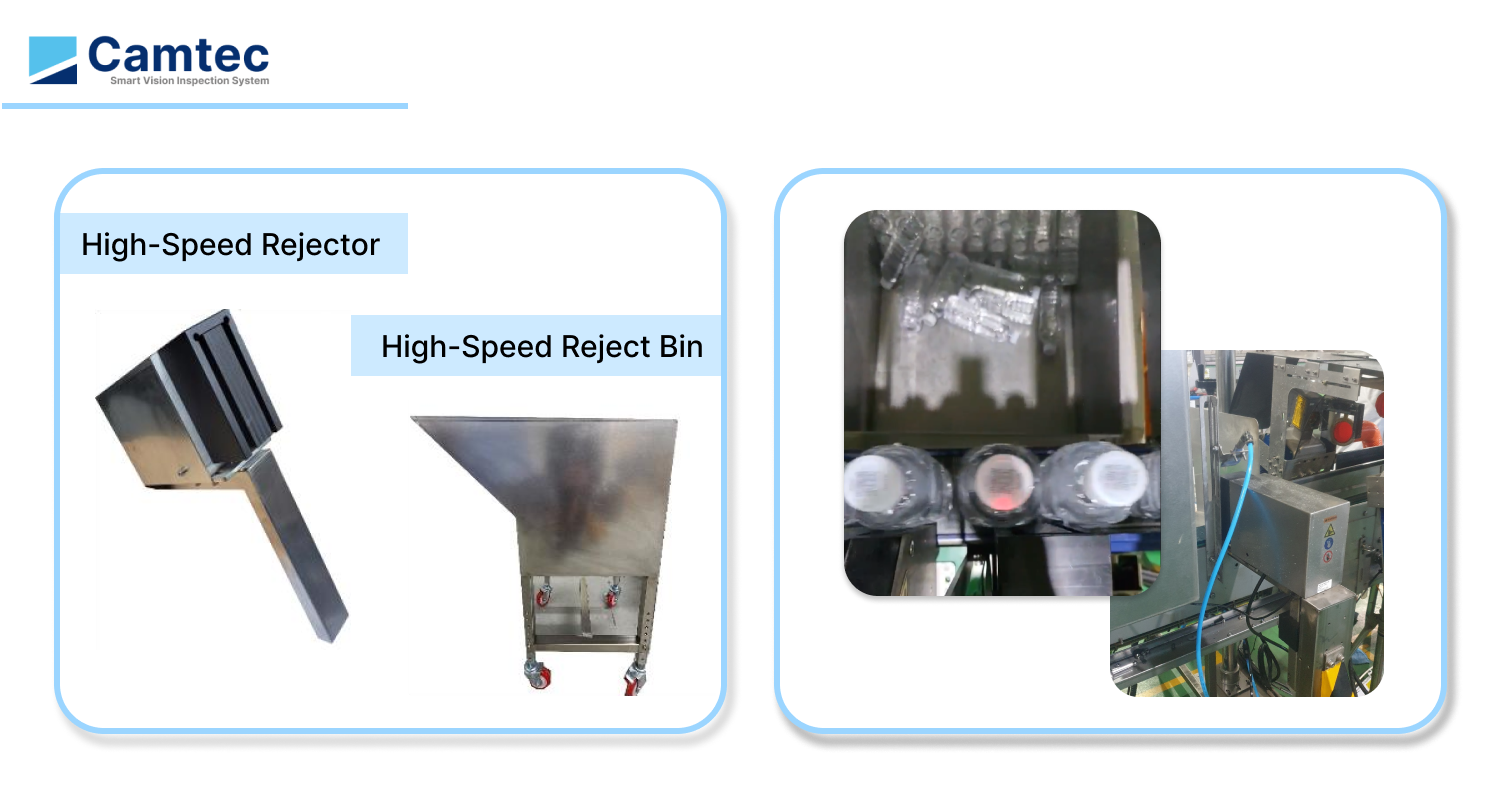

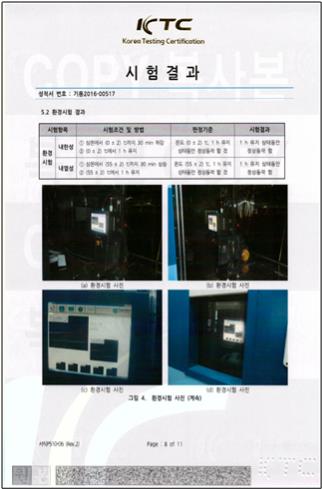

Down Bottle Reject System

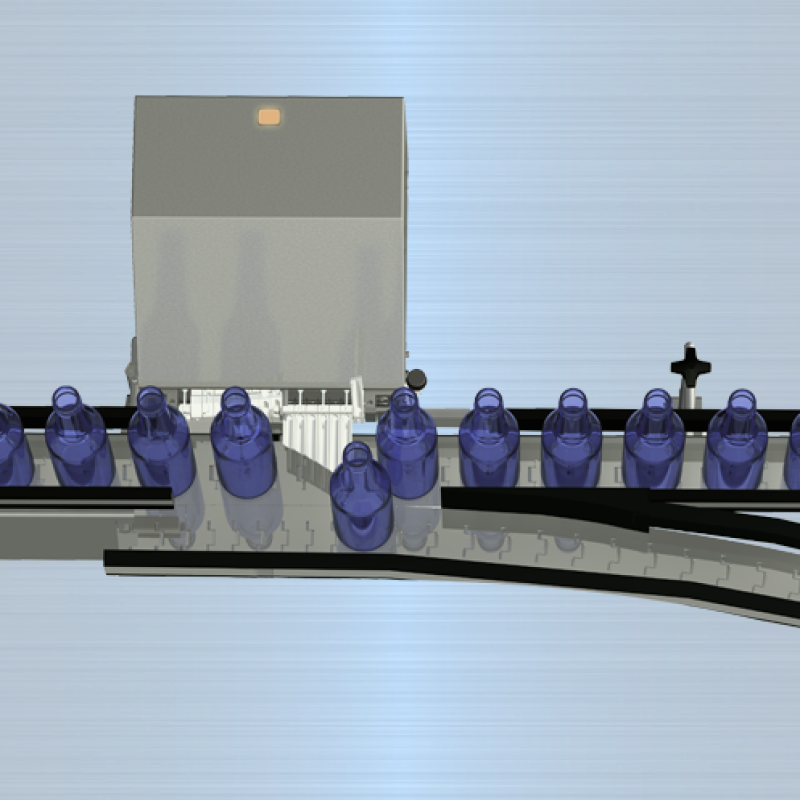

The Down Bottle Reject System is a system designed to identify and swiftly remove bottles that have fallen on the production line, preventing safety incidents caused by fallen bottles and avoiding production interruptions to enhance production efficiency. The system consists of a control unit (PLC), a reject system, and sensors. The control unit receives information from the sensors to identify fallen bottles, and the reject system removes the fallen bottles to their designated locations.

Our company employs a Down Bottle Reject System developed in-house, and its field application results have significantly reduced production downtime due to fallen bottles, enhancing production efficiency and ensuring the stability of the production line.